What is Fieldturf ?

Fieldturf Tarkett, is our partner for Artificial Grass System. The company has the worlds largest market share in terms of installations worldwide.

It has its roots in North America and is the inventor of the artificial grass systems. It was meant to be a surface which replicates natural grass in all its bio mechanical properties.

Initially it was made for use in Stadiums but now has found a major application in landscaping and terrace garden projects

Credited with several patents in the fieldf of Artficial Grass , there is no company in the world that has any product close to what Fieldturf created more then two decades back.

The products is made in USA, and exported all over the world. Infact India's first Artficial Turf based football field was installed at Goa in 2006, at Chougle College, 88,000 Sq.ft.

Since then the company has come a long way in terms of number of key installations , Stadiums (6 Now) , SAARC Region's largest Multi Sport Multi Use field was completed in 2011 at Mizoram , measuring 100,000. Sq.ft

There are lot of brands in the market now , which are mainly sourced from China. Although they are cheaper but not even close to what should feel like grass. Please go through the comparison charts on this page to understand this.

Patented Infill System & Product Properties

Patented Infill System & Product Properties

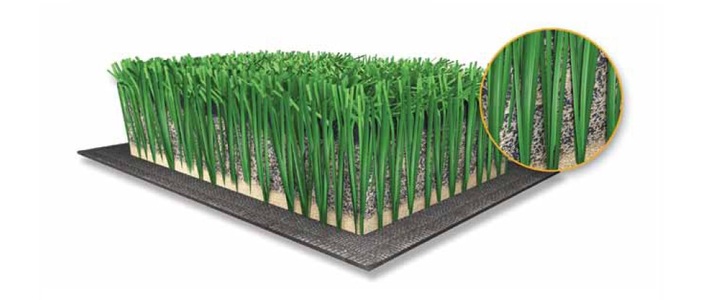

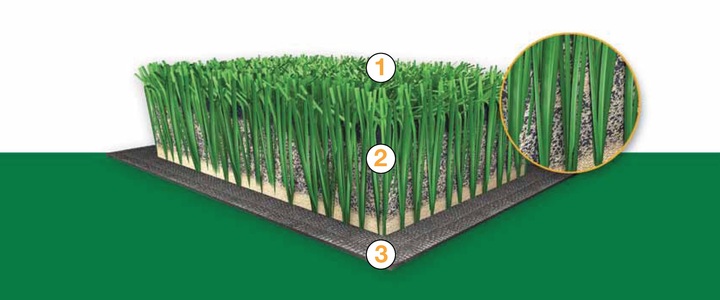

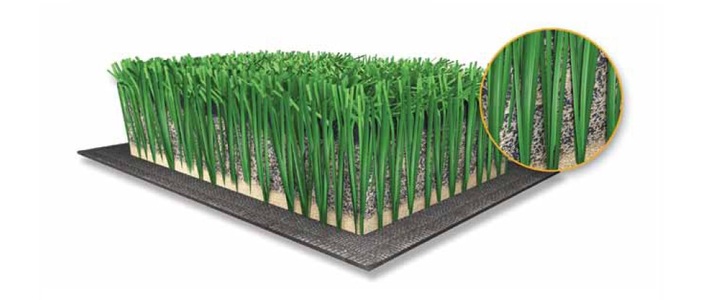

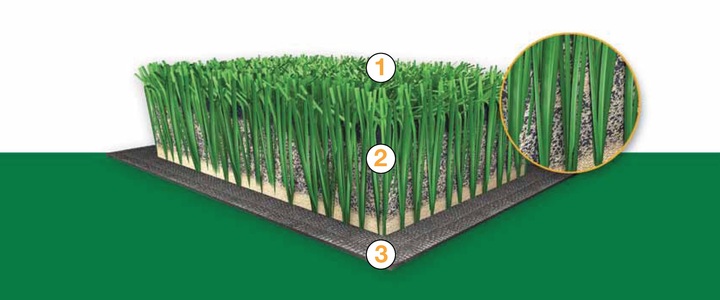

Patented Infill System

When it comes to artificial turf performance and safety, the most important aspect for your field is the infill. Whereby turf fibers are directly related to the aesthetics of the field, the infill – which is spread between the fibers – delivers what the athlete needs; Softness on impact and the correct firmness and cleat-release for ultimate performance.

It is a meticulous process proven with science.

FieldTurf’s patented 3-layered infill system is the only proven method for all levels of sport and the most intricate infill system available on the market.

The bottom layer is comprised of several layers of clean, washed silica sand.

Up to 14 passes of a mix of cryogenic rubber and silica sand is then layered into the system. The rubber and sand particles are a similar size to stay in suspension.

Larger-sized cryogenic rubber top layers ensure that the rubber remains on top, providing a safe, forgiving surface.

Total infill exceeds 9 pounds per square foot on a typical sports field.

Over 720,000 pounds of infill is layered into a typical sports field.

Silica Sand

Stabilizes and supports the system.

Similar size to cryogenic rubber granules in order to eliminate segregation and compaction.

Environmentally beneficial.

Accounts for 70% of total infill weight.

Cryogenic Rubber

Recycled rubber tires are cryogenically frozen and turned into smooth, clean-cut granules.

Rounded granules resist floating or displacement in high-use areas.

Environmentally beneficial.

Accounts for 30% of total infill weight.

The company to its credit has invented the Infill System which is a measured mix of granular silica and spherical rubber granules which provides the artificial grass by Fieldturf the same feel as natural grass even when you walk barefoot on it.

Patented blend of PP & PE make the grass fibers soft and resilient

Surelock technology ensures that backing of fiber is more longlasting then competing products.

The patented design of FieldTurf is radically different from any other synthetic system. While synthetic turf systems might look the same, there are stark contrasts between FieldTurf and the rest. There are three main components to a turf system – fiber, backing, and infill. Here are the basics of a turf system along with how FieldTurf does things differently.

1) Fiber

Turf fibers are responsible for comfort and safety of the player, durability, a natural, grass-like look with soft and pleasing grass-like feel and resilience.

The ideal fibers should reduce skin friction, skin abrasion and offer superior durability, high resilience and temperature stability. Today, turf fibers are made from polyethylene and come in either slit-film or monofilament structures.

2) Infill

The infill system is the single most important aspect of all synthetic turf fields. It is the basis for the safety of the turf system by providing the appropriate cushioning to absorb impact as well as being the foundation to a field’s performance level by offering traction for players to cut, plant and release just like they would on natural grass.

Whereby turf fibers are directly related to the aesthetics of the field, the infill – which is spread between the fibers – delivers what the athlete needs: A safe surface with proper performance attributes. The infill market is becoming more complex with new products being introduced at a rapid rate. With so many choices, it is important to understand the difference between the various systems.

3) Backing

Artificial turf backings are comprised of a primary backing and a secondary backing. Both the primary and secondary backings work together to provide dimensional stability to the entire system.

The primary backing is comprised of woven polypropylene fabrics that allow the artificial turf fibers to be tufted into material in rows and facilitate seaming between artificial turf panels.

The secondary backing is often referred to as the ‘urethane coating’ and is applied to the reverse side of the primary backing in order to permanently lock the tufted fibers in place. Turf backings are either precision coated using the ‘Finger Unit’ method or they are ‘Solid Coated and Perforated’.